The Ultimate Handbook for High-Quality denim Edge-to-Edge Textile

Ever wondered why certain trousers feel like they’re designed for longevity eternity? It’s all about the elements and craftsmanship. Consider the increasing trend of high-end selvedge. This goes beyond common textile—it’s a testament to quality and heritage.

Nowadays, increasingly more individuals are turning to these everlasting textiles for their durability and classic ewingfly denim appeal. Whether you’re a DIY sewist or a denim aficionado, there’s an exceptional aspect about working with top-grade cotton and stitching. It goes beyond merely constructing trousers; it centers on producing a narrative.

Here at Core Fabrics, we’ve assembled a collection of 14.25oz organic cotton and elastic choices. These fabrics are ideal for everything from raw trousers to couture jacket blueprints. Ready to explore the world of top-tier fabrics? Let’s dive in.

Understanding Denim Selvedge Fabric?

Why do some jeans stand out with their distinctive, naturally edged edges? The answer lies in the selvedge denim, a superior material renowned for its enduring strength and old-school appeal. Unlike regular textiles, such material is crafted using time-honored methods that have endured through ages.

The Definition of Selvedge Denim

Selvedge denim is manufactured with retro shuttle looms, which generate minimal widths of about 30-35 inches. They intertwine the material in a manner that ensures self-finished edges, often marked by a characteristic red line. This process ensures the fabric is densely interlaced and highly durable.

Current looms, alternatively, generate wider fabric but fall short of the same level of craftsmanship. Minor flaws in selvedge, like leg twists or uneven textures, are accepted as features of its character. This philosophy, known as “wabi-sabi”, honors the beauty of organic flaws.

The Making of Selvedge Denim

The creation of selvedge denim entails a exacting process. These looms interlace the filling yarns in alternating directions, resulting in a dense and resilient material. This method contrasts with modern looms, which prioritize quick production and efficiency over quality.

Brands like Karson Denim maintain vintage Japanese methods from the 90s. They deliberately incorporate flaws to retain the genuineness of the material. Every item is evaluated on a four-point system, confirming it fulfills the peak requirements of excellence.

| Characteristic | Selvedge Denim | Current Denim |

|---|---|---|

| Width | 30-35 inches | 60+ inches |

| Construction Technique | Traditional Shuttle | Contemporary Loom |

| Texture | Irregular, Flawed | Even |

| Strength | High | Moderate |

“The charm of selvedge lies in its imperfections—every imperfection narrates a tale skill and legacy.”

The Legacy of Selvedge Denim

Evolving from simple roots to worldwide renown, the tale of these fabrics is rich and motivational. Initially designed as rugged attire in seventeenth-century France transformed into a mark of timeless style and craftsmanship.

Beginnings in Craftsmanship

The foundation of this textile dates back to Nîmes, France, where it was referred to as “serge de Nîmes.” Originally designed for workers, it was constructed with sturdy cotton and thread. Its resilience ensured its popularity among workers during the era of the Gold Rush.

During the twentieth century, it had become a staple for pants. The closure of the Cone Mills White Oak facility became a pivotal moment. This change enabled Japanese artisans to restore traditional weaving techniques.

Advancements in Production

After World War II, Japan adopted old-school American culture. Skilled workers repaired classic looms to create genuine reproductions. This devotion to craftsmanship ensured the perseverance of selvedge as a niche product.

Today, innovations from Italy and Turkey have launched environmentally conscious blends and stretch variants. These improvements have enhanced the attraction of this classic textile. At Core Fabrics, we procure internationally, from Montréal to Asia, to offer you the best quality.

“The history of selvedge is a testament to the lasting worth of craftsmanship and legacy.”

The Benefits of Selvedge Denim?

Why does selvedge denim shine in the world of top-tier fabrics? Its distinct attributes and unmatched durability render it popular among enthusiasts and designers alike. Whether you’re making jeans or a tailored jacket, this fabric delivers a mix of classic methods and updated style.

Unique Qualities of Selvedge Fabric

Selvedge denim is celebrated for its dense construction, which enhances ripping resistance and color fading characteristics. In contrast to common fabrics, selvedge denim material is fashioned using classic shuttle looms, creating a tightly packed and more durable fabric. Such a process guarantees that every item possesses a unique texture and personality.

Key features include:

- Textured, firm raw denim contrasts with softened, pre-washed stretch fabrics.

- Through sanforization, sizes become reliable, while untreated fabrics provide a dynamic fitting process.

- Available weights span from 9.5oz Eco Finish to 14.25oz Organic, suited for varied requirements.

Sturdiness and Lifespan

One of the standout features of selvedge denim is its longevity. The tighter weave both reinforces strength and permits distinctive color fades over time. This makes it a valuable investment for those seeking classic garments.

Important aspects:

- Fabrics weighing between 12oz and 14oz are perfect for form-fitting jackets and jeans that mellow with time.

- For classic jean longevity, the 14.25oz True Indigo is a top recommendation.

- Green alternatives, including recycled cotton with indigo blends, contribute to a sustainable collection.

Within our range at Core Fabrics, diverse choices cater to distinct demands. From raw to sanforized, each piece is crafted to deliver exceptional quality and value.

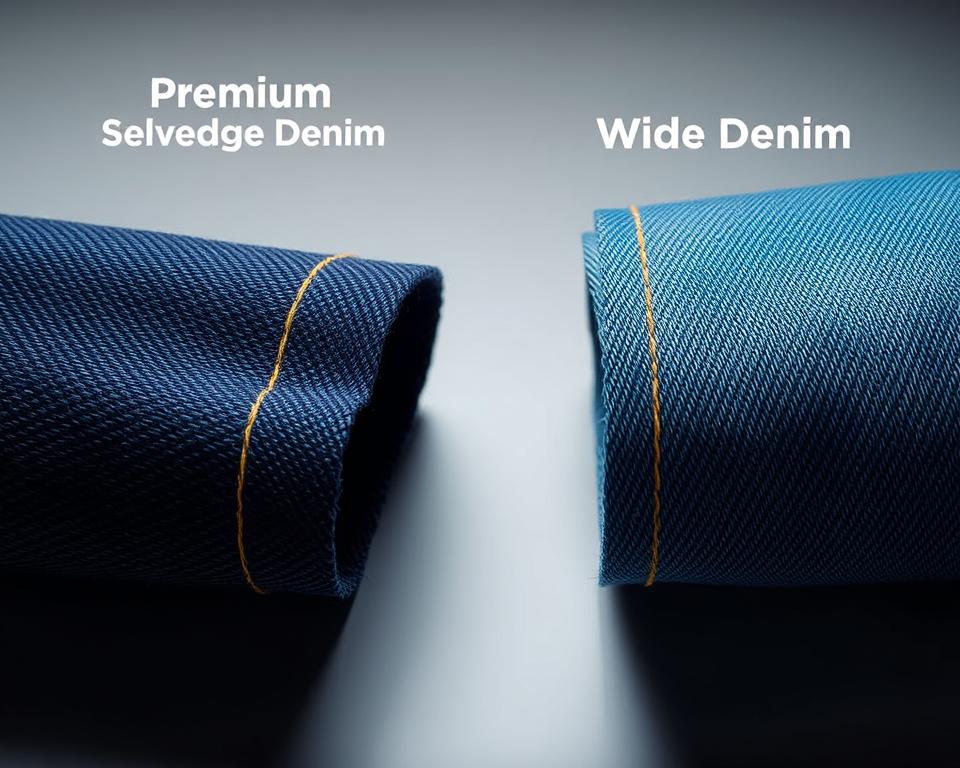

Comparing Selvedge and Wide Denim

For making robust and fashionable apparel, the choice of textile is pivotal. Two common choices include selvedge and wide denim, each with unique characteristics. Comprehending their variances guides the right one for your project.

Key Differences in Weaving Techniques

Selvedge denim is produced using traditional shuttle looms, producing limited spans of 30-35 inches. This herringbone denim material technique forms secure finishes, often featuring a distinctive red line. Conversely, wide denim employs advanced projectile looms, yielding widths of 60 inches or more.

Shuttle looms are slower, producing about 3 meters per minute, while modern projectile looms reach speeds of 30 meters per minute. This difference in speed impacts both the cost and the finish of the end result.

Benefits and Drawbacks

Selvedge denim is known for its premium quality and durability. Its slender dimension suits it well for creations where defined edges and detail work are sought. However, it can be costlier, averaging $23 per meter.

Wide denim is more cost-effective, typically costing $8 per half-meter. Its broader span minimizes excess, ideal for large projects like furniture covering. However, it falls short of the distinctive selvage detail of selvedge.

| Attribute | Selvedge Denim | Wide Denim |

|---|---|---|

| Measurement | 30-35 inches | 60+ inches |

| Weaving Process | Classic Shuttle Loom | Projectile Loom |

| Output | 3 meters per minute | 30 meters per minute |

| Price | $23/meter | $8/half-meter |

For defined borders as seen in Grainline Thayer jackets, selvedge is favored. For larger projects, wide denim offers better value and efficiency. Evaluate your project specifications to choose wisely.

How to Use Selvedge Denim

Working with premium materials can elevate your sewing projects to the next level. Be it making jeans, outerwear, or skirts, grasping fabric quantities, proper sewing methods, and maintenance guarantees a polished result. We will examine the optimal use of this classic fabric.

Material Requirements for Jeans and Jackets

When planning your project, calculating the right amount of material is crucial. Approximately 3-3.3 yards is necessary for men’s jeans, considering defects and shrinkage. Trucker-style jackets generally demand about 3.3 yards, while a skirt often needs 2 yards.

Creative pattern placement can help manage imperfections in the material. Rather than avoiding imperfections, incorporate them into your pattern for distinctive style.

| Project | Yardage Needed |

|---|---|

| Men’s Jeans | 3-3.3 yards |

| Trucker-Style Jacket | 3.3 yards |

| Skirt | 2 yards |

Advice for Sewing and Longevity

Employing proper equipment and methods leads to an impeccable finish. Choose #70–110 pins and presser foot attachments suitable for thick fabrics. Gütermann rPET thread works well for contrasting stitches.

Here are some additional tips:

- Use a tailor’s clapper for sharp creases without shine.

- Core Fabrics’ denim kits include topstitch thread, rivets, and 9mm jeans buttons for a professional finish.

- For structured edges, like those in jackets, selvedge is the preferred choice.

Proper care extends the life of your creations. Use minimal washing and opt for air drying to preserve fabric quality. Adhering to these practices will sustain your creations for years.

To Conclude

Working with high-end textiles is not solely about longevity; it’s about infusing character. Selvedge denim embodies this ideology, merging artisanal charm with long-lasting quality. From jeans to tailored jackets, every stitch of this material conveys a narrative.

With Core Fabrics, unleashing your creative potential is effortless. Our swatch service lets you touch and test the fabric before deciding. Additionally, benefit from complimentary shipping on orders exceeding $150 USD throughout North America.

Looking ahead, eco-friendly blends and vintage washes are shaping the future of cotton textiles. Such innovations provide novel methods for infusing eco-consciousness and fashion into your closet.

Eager to explore top-tier textiles? Start shopping today to experience purposeful design. Your future project might just be that lasting masterpiece.